CHANCE® Helical Piles Foundation Anchor System

CHANCE® Helical Piles have found increasingly widespread use as a direct result of the versatility and cost-effectiveness of the helical foundation system. The ability to utilize helical piles in both compression and tension applications makes the manufactured foundation system an attractive alternative for deep foundation construction. Discover how you can get the performance of traditional deep foundation systems without the high mobilization costs, spoils and vibrations.

CHANCE® Helical Piles have found increasingly widespread use as a direct result of the versatility and cost-effectiveness of the helical foundation system. The ability to utilize helical piles in both compression and tension applications makes the manufactured foundation system an attractive alternative for deep foundation construction. Discover how you can get the performance of traditional deep foundation systems without the high mobilization costs, spoils and vibrations.

Quick to install. Built-in advantages.

Helical piles have the built-in advantage of rapid installation with small equipment, immediate loading capabilities and cost efficiency when compared with traditional foundation methods. Helical piles also feature built-in quality control through real-time tracking of the torque-to-capacity ratio during installation. View the CHANCE® Helical Piles Brochure.

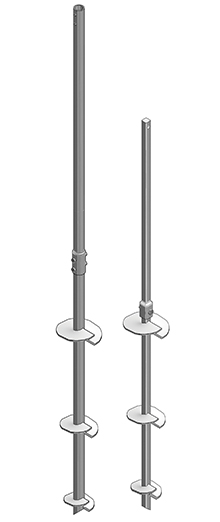

The Composition of a Helical Pile

A helical pile can be a solid square steel shaft, a round shaft open steel pipe pile or a combination of both square and round with one or more helical plates welded to the pipe near the tip. Helical piles are installed by rotating the shaft of the pile. As the shaft rotates, the helical plate advances into the ground “pulling” the shaft with it. This action is much like a wood screw. A helical pile is generally used to resist compression and lateral loading.

Segments or sections of CHANCE® Helical Piles are joined with bolted couplings. Installation depth is limited only by soil density and practicality based on economics. A helical bearing plate or helix is one pitch of a screw thread. All helices, regardless of their diameter, have a standard 3” pitch. Being a true helical shape, the helices do not auger into the soil but rather screw into it with minimal soil disturbance. Helical plates are spaced at distances far enough apart that they function independently of each other as individual bearing elements; consequently, the capacity of a particular helix on a helical pile shaft is not influenced by the helix above or below it.

Working on a design project using helical piles and anchors? HeliCAP™ is a free civil engineering software platform that helps calculate capacity requirements for CHANCE® Helical products. Control for soil parameters, environmental variables, and other essential criteria to select the appropriate pile/anchor size needed for your individual project requirements.

CHANCE® Helical Pile Applications

- Boardwalk Foundations

- Bridge Foundations

- Communication Tower Foundations

- New Construction Foundations

- Pipeline Foundations

- Solar Foundations

- Swimming Pool Foundations

CHANCE® Helical Piles Case Studies

- Dry Tortugas National Park

- Rumfish Aquarium

- Historic Jefferson High School Restoration

- Bayline Railroad - Train Engine Shelter

- BJ's Brewhouse

Request a Quote

Have questions about any of our CHANCE® Helical Piles? Ready to get started on your next project? Looking for expert advice? Request a quote now to speak with our professional team of experts about specifications, pricing, and any additional questions you may have. We’ll get back to you within one business day.

Helical Piles FAQs

What is a helical pile?

A helical pile, also known as a screw pile or helical pier, is a deep foundation system used to support structures. It consists of a central steel shaft with one or more helical plates (similar to screws) welded to it. The pile is driven into the ground by rotating it, which allows the helical plates to pull the pile deeper into the soil.

How are helical piles installed?

Helical piles are installed by rotating the shaft of the pile with a hydraulic drive head mounted on an excavator or other machinery. As the shaft rotates, the helical plate advances into the ground “pulling” the shaft with it. This action is much like a wood screw.

How far apart should helical piles be spaced?

Helical piles should be spaced at a minimum of three times (3x) the diameter of the largest helical plate, center to center. We typically use the largest helical plate, so for a lead section with an 8”/10”/12” helix configuration, the minimum spacing should be 3 x 12” = 36” center to center.

The helical pile minimum spacing is only important down at bearing depth where the helical plates are, so if you have multiple piles under a pile cap and you want to minimize the area of the pile cap, you can typically install the helical piles at a batter (angle) to get the separation you need at bearing depth and the piles can be terminated in a smaller footing. If the helical piles do have to be installed closer than the minimum, you can use normal group effect formulas to de-rate the capacities accordingly.

Why does CHANCE offer four different shaft types?

CHANCE® offers four (4) different shaft types because not all soil conditions are conducive to every type. For instance, some soil conditions are simply too hard for an all-pipe shaft pile to install effectively, so a square shaft pile or even a combination pile would be a better and more efficient choice in harder soil conditions. By contrast, in weak/loose soils conditions that will have appreciable compressive loads, one of the round shaft options most likely will be the best choice.

How much does a helical pile cost?

That’s a lot like calling the local car dealership and asking, “How much does a car cost”? For both the car and the helical pile, it really depends on what you need. There’s no such thing as a one-size-fits-all helical pile. The cost of a pile varies with shaft type, shaft size, length of the pile, installation cost and to a lesser extent, the helix configuration. Helical pile shafts are available in various shapes and sizes.

The size and shape of the shaft you need for any given application depends on the magnitude of the load capacity needed and the strength/properties of the soil you are screwing them into. Accordingly, to determine what the cost of your pile would be, we would need to know the magnitude of the load to be resisted, the application (i.e. new construction pile, earth retention anchor, etc.) and the site-specific soils data (preferably an SPT boring). We offer free estimates and can give you a better feel for the costs once we understand the conditions specific to your situation.